Remarkable New Fabric Efficiently Transfers Heat – Could Help Keep You Cool Even Without A/C

Air conditioning and other space cooling methods account for about 10% of all electricity consumption in the U.S., according to the U.S. Energy Information Administration. Now, researchers reporting in ACS Applied Materials & Interfaces have developed a material that cools the wearer without using any electricity. The fabric transfers heat, allows moisture to evaporate from the skin and repels water.

Cooling off a person’s body is much more efficient than cooling an entire room or building. Various clothing and textiles have been designed to do just that, but most have disadvantages, such as poor cooling capacity; large electricity consumption; complex, time-consuming manufacturing; and/or high cost. Yang Si, Bin Ding and colleagues wanted to develop a personal cooling fabric that could efficiently transfer heat away from the body, while also being breathable, water repellent, and easy to make.

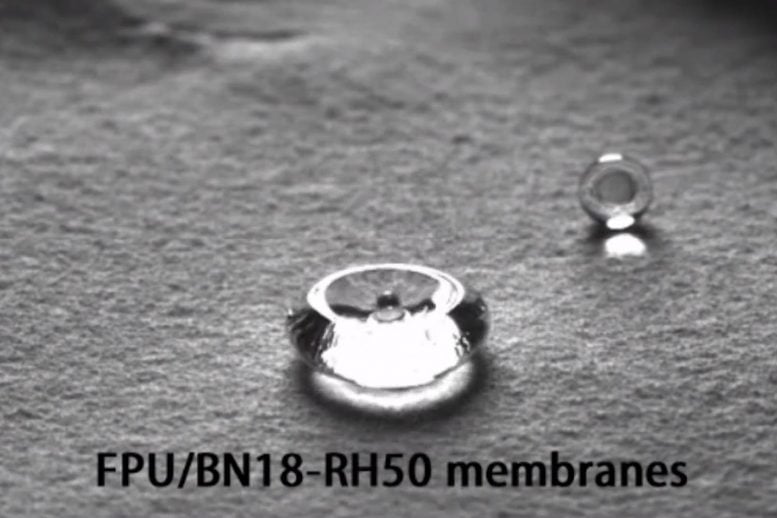

The researchers made the new material by electrospinning a polymer (polyurethane), a water-repelling version of the polymer (fluorinated polyurethane) and a thermally conductive filler (boron nitride nanosheets) into nanofibrous membranes. These membranes repelled water from the outside, but they had large enough pores to allow sweat to evaporate from the skin and air to circulate. The boron nitride nanosheets coated the polymer nanofibers, forming a network that conducted heat from an inside source to the outside air. In tests, the thermal conductivity was higher than that of many other conventional or high-tech fabrics. The membrane could be useful not only for personal cooling, but also for solar energy collection, seawater desalination, and thermal management of electronic devices, the researchers say.

###

Reference: “Thermoconductive, Moisture-Permeable, and Superhydrophobic Nanofibrous Membranes with Interpenetrated Boron Nitride Network for Personal Cooling Fabrics” by Xi Yu, Yang Li, Xianfeng Wang, Yang Si, Jianyong Yu and Bin Ding, 1 July 2020, ACS Applied Materials & Interfaces.

DOI: 10.1021/acsami.0c04486

The authors acknowledge funding from the National Natural Science Foundation of China, the Interdisciplinary Studies Program for the Central Universities and the Fundamental Research Funds for the Central Universities.

Can it be put on walls, furniture, beds, car seats and other things and do any good for us.